Avant Ball Links technology

Back on 2006 during the design of the Aurora there was one concern we had and that was the ball link systems currently in use by most helicopters. Being that the size of the engines have been increasing, for the most part the rest of the parts have been adapting but the ball link technology has not changed much to reflect this increase in stress loads.

We did a lot of testing using several different brands and although some were acceptable they still had the tendency to pop-out under certain repetitive high stress maneuvers.

Examining the how the ball links wear and what determined the likelihood of a ball failing we determined that we had to address a few aspects of the ball design to minimize the possibility of failure in flight.

Doing so presented several complications because what we wanted to do wasn’t easy to achieve without hurting other aspects of the performance.

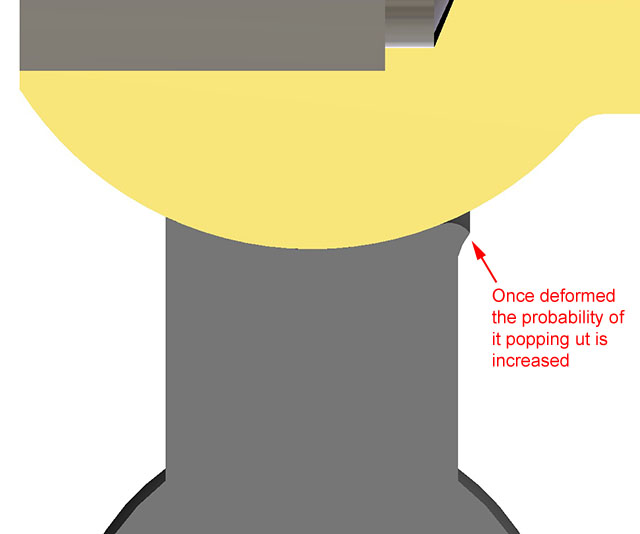

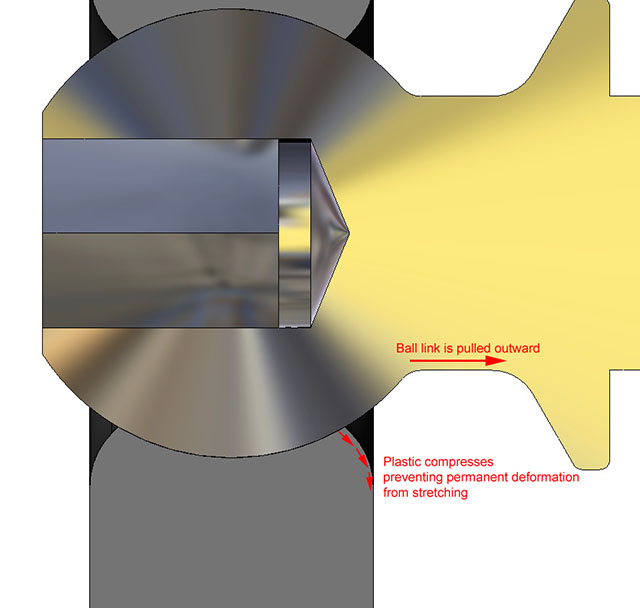

From examination of the standard balls after use we found evidence of an edge deformation that could potential make the ball fail in flight.

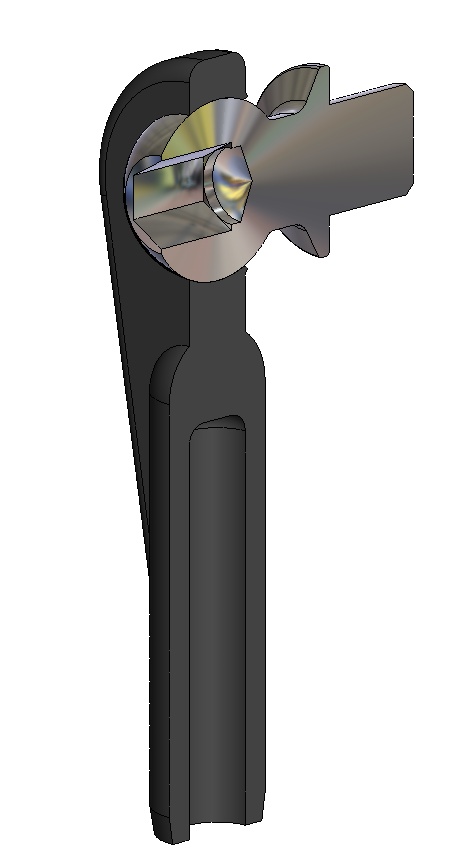

Here’s a cross section view of a standard ball link:

In this detail you can see the typical wear that the ball will have after some use.

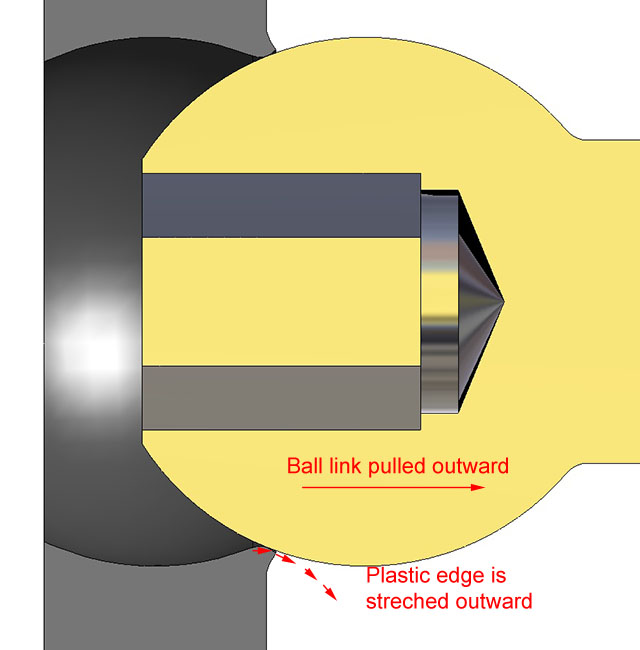

The reason for that is that the edge of the ball is stretched outward when the ball is pulled out of the ball link creating a shape like this after a while making it easier for the ball link to come out in flight.

The kind of plastic used in most ball links is good for compression but not so good for elongation (stretching). Due to this problem most manufacturers add rubber to the plastic formulation making it more resistant to elongation but with the unwanted side effect that it also makes it easier for the ball to pop out.

Most manufacturers try to find a balance between the two so that it gives a reasonable durability and not too much of a “rubbery” feel to it.

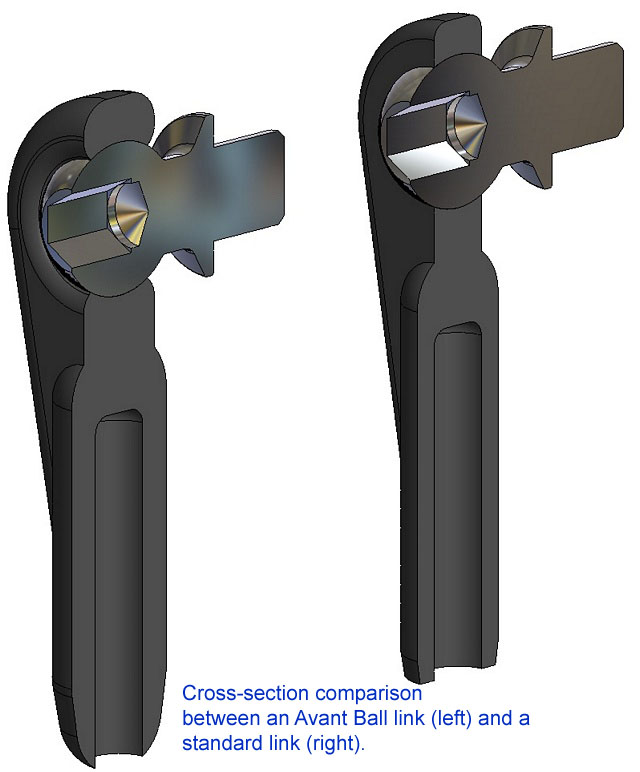

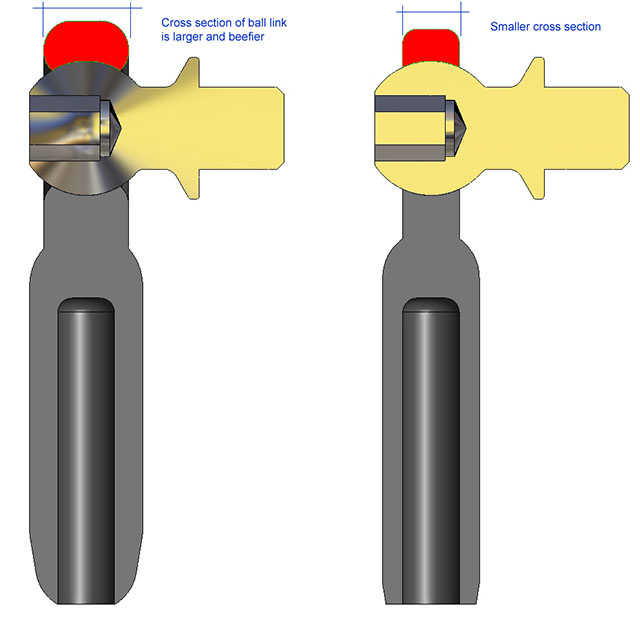

Let’s look at the Avant balls and a standard ball:

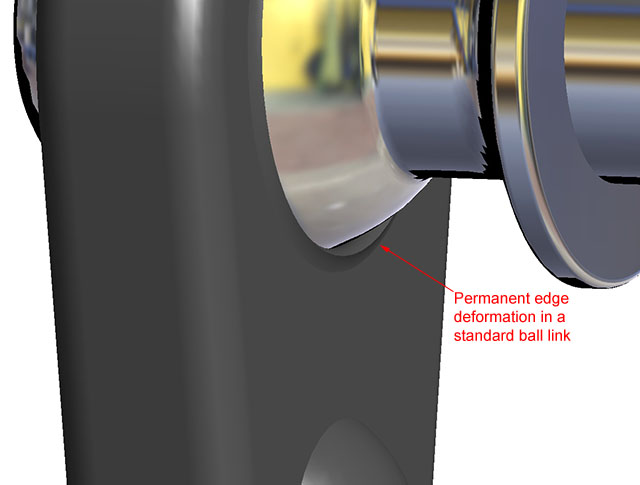

First you can see a cross section of both and an obvious difference in the cross section of the ring around the ball. This was the area with the most failures we found in the standard balls so a different shape and cross-section area was designed for the Avant ball link. From failure stress simulation and from actual crash results we now know that the ring around the ball is extremely strong and that the failure point is more likely be in the plastic around the rod section.

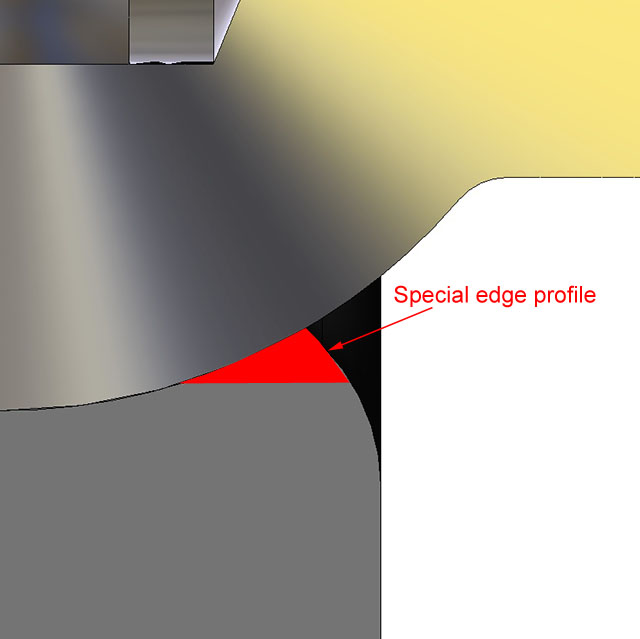

You can see the section where they differ. This profile shape is the result of research to make this ball more resilient to the effects from insertion and extraction.

On this detail you can see the advanced edge profile designed by Avant that’s used in the Avant ball links.

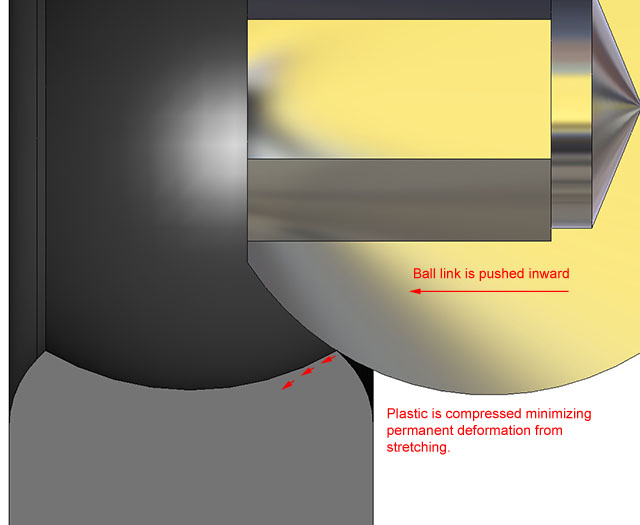

The way this profile works is by eliminating the stretching that happens when the ball is pulled out of the ball link

Or when it’s pushed into the ball link

This advanced edge shape also makes it possible to use the links in both sides without concerns making fine-tuning the helicopter much easier because you can use half turns to fine tune the response.

This profile allowed us to eliminate the rubber from the ball link making it much less “rubbery” and replace it with a special elastomer that has memory shape and that can be reactivated by heat. This makes the insertion and removal of the balls much harder and to the point that it’s very likely that you’ll need to use ball link pliers in most cases. We traded convenience of hand installation for more difficult pliers installation but with the added security of making it harder to come out.

Keep in mind that the important thing is to make sure your ball links are secure so check and make sure the balls don’t come out easily.

Can be used on both sides

Another Advantage of the technology used in the Avant Ball links is that because of the special profile they can be used in either side so half-a-turn adjustments are possible.

Hopes this explains this technology invented by Avant and how to use it.

Avant RC.